Introduction to IECEX Rating for Torches and Lighting

When working in hazardous environments, even the seemingly simple task of illumination requires careful consideration. Torches and lighting equipment can become potential ignition sources if not properly certified for the specific dangers present. Here’s where the IECEX rating steps in, acting as a vital safety assurance for personnel operating in these high-risk zones. This globally recognised certification (**note this is the accepted rating we use in Australia) scheme evaluates equipment against rigorous standards, ensuring it minimises the risk of sparks or heat generation that could trigger an explosion. By employing IECEX-rated torches, headlamps and lighting, workers are afforded peace of mind, knowing their equipment has undergone stringent testing to withstand the challenging conditions encountered in hazardous areas. Furthermore, adhering to IECEX certification demonstrates a commitment to workplace safety and regulatory compliance, minimising the potential for accidents and costly downtime avoiding harm to people and property. In essence, the IECEX rating serves as a cornerstone for safe and efficient illumination in environments where a single spark could have devastating consequences. By prioritising this certification, we ensure continued productivity and, most importantly, the well-being of those working on the frontline.

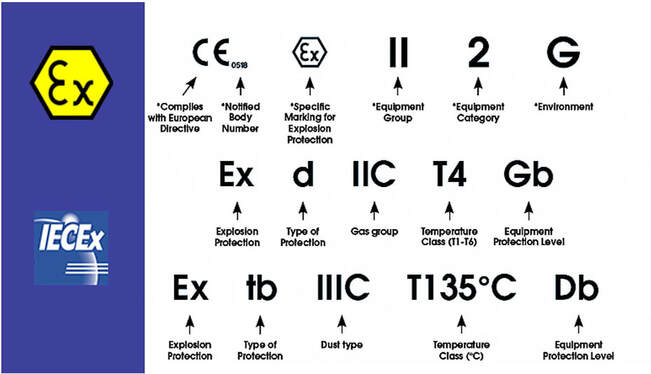

Understanding IECEX Rating

IECEX stands for International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres. This mouthful of a name translates into a globally recognized certification system that ensures equipment can be safely used in environments where explosions are a potential hazard. Imagine oil refineries, gas pipelines, chemical plants, even flour mills – all places where flammable materials or dust particles could create a dangerous mix with air. The IECEX system steps in by putting equipment through rigorous testing based on international standards. This testing verifies the equipment’s design and construction can withstand the specific threats present in each hazardous area. By achieving IECEX certification, manufacturers demonstrate their equipment minimises the risk of sparks, heat generation, or other potential ignition sources. In essence, the IECEX system acts as an independent safety watchdog, fostering trust and confidence that the equipment won’t become the very spark that ignites a disaster.

Types of IECEX Rating

There are two types of IECEX ratings: Ex d and Ex e. The Ex d rating is given to equipment that has been designed and tested to contain any explosion within itself, while the Ex e rating is given to equipment that prevents an explosion from occurring in the first place.

Importance of IECEX Rating for Torches and Lighting

In hazardous environments, illumination becomes a critical safety consideration. A stray spark from an uncertified torch can have catastrophic consequences, transforming a routine operation into a potential inferno. This is precisely why the IECEx rating plays such a crucial role. This internationally recognised certification system ensures that torches and lighting equipment undergo rigorous testing to meet the necessary safety standards for use in potentially explosive atmospheres. Imagine oil refineries, chemical plants, or even dusty flour mills – all locations where flammable materials or airborne particles could create a dangerous mix with air. The IECEx certification process meticulously evaluates the design and construction of torches and lighting, verifying their ability to withstand the specific threats present in each hazardous zone. By achieving IECEx certification, manufacturers demonstrate their commitment to creating equipment that minimises the risk of sparks, heat generation, or any other potential ignition sources. In essence, the IECEx rating acts as an independent safety watchdog, fostering trust and confidence that the torches and lighting used by personnel won’t become the very spark that ignites a disaster. This focus on safety not only protects workers but also minimises potential downtime and costly accidents, ensuring continued productivity in these high-risk environments.

Conclusion

In conclusion, using torches and lighting in hazardous environments requires careful consideration of safety certifications. The IECEX rating is a globally recognised standard that ensures the equipment has been tested and approved for use in potentially explosive atmospheres.

Other certifications such as ATEX and UL are also important depending on the location of use. It is crucial to always prioritise safety when working in hazardous environments, and choosing equipment with the appropriate certifications is a vital aspect of this.

So, it is recommended to always check for these ratings before purchasing any torches or lighting for use in potentially explosive atmospheres.

Stay safe! In addition, regular maintenance and proper usage of the equipment are also important for ensuring continued safety.